The engine in #77 came from the old '77.5 automatic car, which had 158kmi before it

was removed from that car (which was scrapped). While it is not in serious need of a

rebuild, starting our first season with a fresh motor is certainly a good idea, and

made even more sense as the engine had to be swapped anyway - #77 came cheap thanks to

a blown motor in it! It had clearly been drag-raced (no proper use for a Porsche!) by

the teenager who'd gotten the keys to it, and he'd managed to burn up pistons and

valves, blow the head gasket, scorch the pressure plate, flywheel, and clutch, and do

who knows what else damage to it! The situation was so bad that, because the engine

sat for a while in the garage with the head off but not drained, the inside of the

block (including the bores) has suffered damage from corrosion due to the large amount

of water mixed with the oil in the sump. That engine is now resting in various

location, in pieces, and hopefully can be used as a core to build a full-out race

motor for a future season (once the chassis and driver are sorted out and tuned).

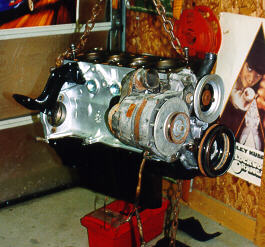

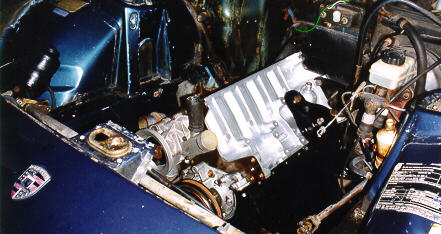

In contrast, the work with the donor car's engine was extremely limited. We knew it

was in good shape before we pulled it, as we'd put many of those miles on it without

any problem and knew that it was in great shape. Earlier in the summer we had run a

compression and leakdown test on it, and still (at 158kmi) got compression on the high

end of the factory spec (~150psi = 10 bar, factory spec was 8-11 bar, with 8.5:1

compression) and leakdown less than 10% (as low as the gauge went). We had also

performed a head gasket replacement a year earlier and knew the top end was in good

shape at the time.

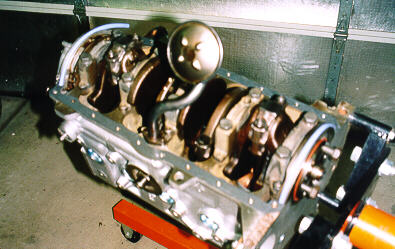

This was confirmed when we tore apart the engine; after removing the pistons we

could still see the cross-hatch pattern from the original hone that was performed in

the factory 22 years and 158kmi ago! All bearings were in excellent shape, with hardly

any scratching or wear at all.

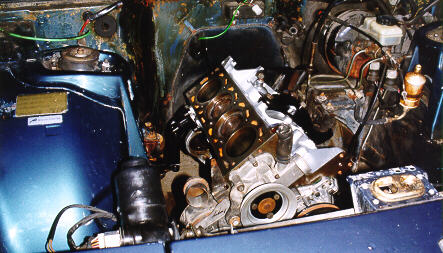

The engine received new bearings, rings, gaskets and seals, and we balanced the rods

and pistons; the block was completely cleaned and repainted. Compression and all other

specs are as original, though the compression ratio could still be raised legally (per

SCCA IT specs); our focus was making a reliable inexpensive engine that will last long

enough for the driver to learn how to race! The only mods (as such) were balancing

rods and pistons. The engine was re-installed and run prior to Thanksgiving 1999.

Running revealed that the oil pan was leaking pretty badly, requiring the pan be

removed and re-sealed. This was done the following spring (2000) prior to Driver's

School.

Still to come for this engine are an improved exhaust and header, improved ignition

tuning and control, and revised cam timing (though the cam must remain stock in IT).